Transform Your Screening Process: Check Out Cutting-Edge Innovation in Star Screen Tools

Boost Your Recycling Workflow With Disc Screens

By utilizing sophisticated innovation and ingenious design, disc screens supply a promising remedy to enhance reusing operations. In this conversation, we will certainly discover how disc screens enhance arranging efficiency, make best use of product splitting up, rise reusing speed, and boost total efficiency. Join us as we delve into the globe of disc screens and find the lots of means they can improve your reusing procedures.

Just How Disc Screens Enhance Arranging Efficiency

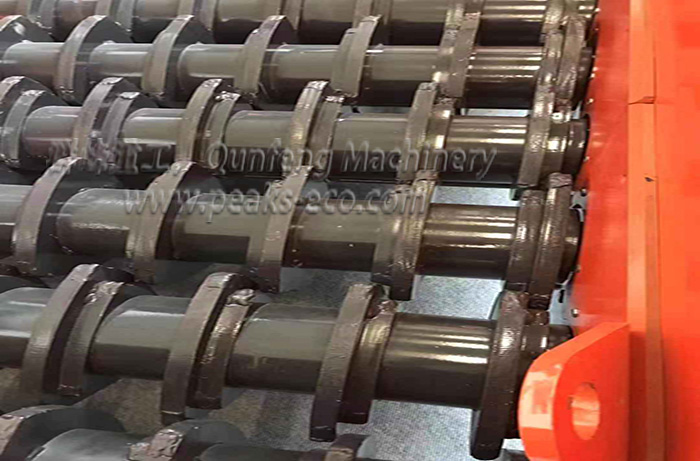

Disc screens play an important duty in enhancing sorting effectiveness in reusing operations. These screens are created to separate materials based on shape, dimension, and weight, enabling for much more reliable sorting of recyclable materials. By utilizing turning discs with tactically put openings, disc screens can rapidly and precisely separate various sorts of materials.

Among the vital methods in which disc displays improve sorting performance is via their ability to deal with high volumes of product. The turning discs permit for continuous material feed, making certain a constant flow of recyclable materials via the arranging process. This eliminates the need for hand-operated sorting and reduces the threat of bottlenecks or blockages in the system.

Furthermore, disc displays are highly customizable, allowing for accurate sorting based on details product demands. The size and spacing of the discs can be gotten used to suit various product dimensions, making certain that each material stream is effectively arranged. This level of personalization improves the overall precision of the sorting procedure and decreases the possibility of contamination or waste.

Furthermore, disc screens are designed to be sturdy and low-maintenance, lessening downtime and taking full advantage of functional performance (star screen). They are developed to endure the demands of durable recycling operations and require marginal upkeep. This allows reusing centers to maintain consistent arranging performance without considerable interruptions

Making The Most Of Product Splitting Up With Disc Screens

With their capability to take care of high quantities of material and personalized design, disc screens play an essential role in making best use of material splitting up effectiveness in reusing procedures. These displays are specifically created to separate various kinds of materials based on shapes and size, enabling efficient sorting and healing of recyclable products.

Disc displays work by rotating discs, which have different dimensions and forms of openings, to different materials as they pass through. As materials are fed onto the discs, smaller sized fragments fall via the openings while bigger ones continue to travel along the surface area.

Among the crucial advantages of disc displays is their capacity to handle high quantities of product. Their big testing surface area permits efficient handling, decreasing the moment and labor required for hand-operated sorting. Additionally, disc displays can be personalized with different disc sizes and configurations to suit the particular requirements of reusing procedures, further improving their product separation capacities.

Boosting Recycling Rate With Disc Screens

To enhance reusing performance, disc screens provide the prospective to substantially enhance the rate at which products are processed. Disc screens are an essential part in reusing operations, aiding to separate various kinds of products efficiently. By executing disc screens in reusing centers, operators can streamline their processes and improve total performance.

Using disc screens permits a continual circulation of materials, which removes the need for hand-operated sorting and lowers downtime. These screens are geared up with turning discs that have numerous sizes and spacings, permitting the separation of various materials based on their shapes and size. As products overlook the discs, smaller items drop with the spaces, while bigger items continue down the conveyor belt.

Among the main advantages of utilizing disc displays is their capability to take care of huge volumes of materials rapidly. This increased speed of processing assists reusing facilities to meet the growing demands for recycled products. By minimizing the moment it requires to type and different products, disc screens allow reusing procedures to run a lot more efficiently and successfully.

In like it enhancement to boosting reusing rate, disc screens additionally contribute to the overall top quality of the recycled products. With their specific separation capacities, disc screens can properly eliminate pollutants and undesirable products from the reusing stream. This makes sure that the end product meets the desired quality criteria, making it a lot more important and marketable.

Improving Recycling Effectiveness With Disc Screens

Can disc screens be used to improve the effectiveness of reusing operations? The response is a definite yes. Disc screens are an innovative technology that can dramatically enhance the reusing procedure by dividing materials much more effectively and properly. By utilizing turning discs with strategically positioned openings, disc screens can divide numerous products based on size, density, and shape.

One of the vital benefits of disc screens is their ability to get rid of contaminants from the recycling stream. The rotating discs enable the splitting up of smaller items such as plastic, paper, and steel, while bigger items like cardboard and glass remain in addition to the display. This not just boosts the quality of the recycled materials but additionally reduces the danger of damages to handling equipment.

Additionally, disc screens can assist boost the recovery rates of important products. By accurately separating various sorts of materials, disc displays make it possible for reusing centers to draw out a greater percentage of recyclables from the waste stream. This not just optimizes resource recovery but likewise reduces the need for virgin materials, leading to a much more lasting and environmentally friendly recycling process.

In addition to boosting reusing effectiveness, disc screens likewise use operational benefits. They are created to be low-maintenance and resilient, lessening downtime and boosting overall efficiency. Additionally, disc screens a fantastic read can be quickly integrated right into existing recycling systems, making them an economical solution for improving recycling procedures.

Enhancing Performance With Disc Screens

Disc displays not just enhance the performance of reusing operations but additionally boost efficiency at the same time. By utilizing this innovative innovation, recycling facilities can improve their procedures and achieve greater degrees of performance.

One key benefit of disc screens is their capability to different products properly and accurately. As materials pass through the discs, smaller items fall via the holes while bigger products proceed down the conveyor belt.

In addition, disc screens are designed to deal with large volumes of products at a quick pace. With their durable building and high-speed turning, these displays can effectively process huge quantities of recyclables in a shorter amount of time. This enhanced efficiency allows recycling centers to take care of even more products, fulfill higher need, and ultimately generate higher revenue.

Additionally, disc screens are created to lessen downtime and maintenance requirements. Their long lasting components and progressed engineering make certain trusted efficiency, decreasing the requirement for frequent repairs and replacements. Consequently, operators can concentrate on taking full advantage of performance rather than taking care of tools problems.

Final Thought

By using rotating discs with strategically put blog here openings, disc displays can rapidly and properly separate different types of products.

The turning discs allow for continuous material feed, making certain a consistent flow of recyclable products with the arranging process.Disc displays work by turning discs, which have numerous sizes and shapes of openings, to separate products as they pass through. In addition, disc displays can be tailored with various disc sizes and configurations to accommodate the certain demands of reusing operations, even more enhancing their product separation capacities.

By utilizing revolving discs with tactically positioned openings, disc screens can divide various materials based on thickness, dimension, and form.